- September 24 2024

- admin

UltraVision Consult Launches the Latest Generation of the M.A.R.C.A. Solution, Based on Cloud Technology

UltraVision Consult is continuously focused on developing and perfecting the solutions within its portfolio. One of the company’s top priorities is the solution for the Automatic Vehicle Weighing Reporting Module (M.A.R.C.A.), aimed at creating an efficient way to operate complex and modular electronic vehicle weighing platforms. The technology is under constant development to provide a more advanced platform through which monitoring, control, and reporting processes become easier and safer for users.

With the release of the new version, M.A.R.C.A 3.0, all system operations can be carried out remotely by integrating a hardware assembly on the weighing platform. This setup automatically collects vehicle-related information, such as license plate numbers, type of cargo, and driver details. Additional necessary information can be manually entered into a controller installed in the operation cabin or automatically through scanning the driver’s card or a QR code issued by the company.

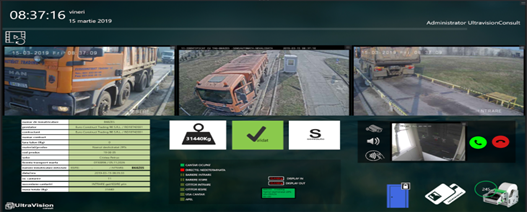

After all data is collected, it is processed in the cloud through the AppBalance application, which ensures data and event processing in a database via communication protocols. This process eliminates the possibility of human error due to the standardized procedure implemented. All safety and control elements can be operated remotely through the Cloud Balance web application using the hardware infrastructure and software systems for calculation and reporting algorithms. The hardware solution includes:

- A device for collecting weight data,

- Traffic lights to inform the driver,

- Surveillance cameras for correct vehicle alignment on the weighing platform,

- IR sensors to detect the vehicle’s position and direction,

- LPR (License Plate Recognition) systems for license plate identification,

- LED panels to inform the driver of the appropriate steps through messages such as: FORWARD, STOP, INCORRECT POSITION, OCCUPIED, PRINT RECEIPT, VALIDATE,

- Passive tags for vehicle identification,

- Driver identification through QR code readers or a card reader,

- An intercom for communication and weighing process calculation algorithms,

- A receipt printer or a multifunctional device (printer) for document printing.

On the console panel installed within the company premises, all manually entered or automatically collected information can be found. The panel also includes buttons specifically implemented for manually selecting the type of cargo and load type (empty or full).

Thanks to the software platform and hardware infrastructure, the entire reporting operation will be executed automatically, with all data transferred to a database. The software elements allow real-time observation of the weighing procedure and subsequent verification with all included information retrieved from the database.

The purpose of the new M.A.R.C.A. version is to bring tangible benefits to customers. By implementing the automation solution, operational efficiency increases significantly by creating a standardized, fast, and intuitive way of working for both drivers and weighing process operators. Additionally, by eliminating the need for a physical operator, the risk of incorrect weighing operations is practically impossible due to the implemented hardware solutions and subsequent weighing process in the Cloud Balance platform.

Cost reductions also result from eliminating the need for personnel to be physically present during the weighing operations. Moreover, the reduction or even elimination of resources such as computers, registers, and other devices needed for reporting weighing operations reduces operating costs and provides greater control over all collected information.